In today’s highly competitive construction, mining, and aggregate industries, efficiency and reliability are essential. As the demand for high-quality crushed materials grows, equipment manufacturers are continually innovating to meet evolving expectations. Among these machines, the jaw crusher remains one of the most widely used tools for primary crushing due to its versatility, simplicity, and powerful performance. Recent advances in jaw crusher design are now pushing the boundaries of output capacity, durability, and energy efficiency—transforming the way materials are processed across various sectors.

In this article, we explore the latest innovations in jaw crusher technology and how they compare with other machines such as cone crushers, impact crushers, and traditional crusher machines.

1. What Is a Jaw Crusher and Why It Matters

A jaw crusher is a type of crusher machine used to break down large stones or ores into smaller, manageable pieces. It uses two crushing jaws—one fixed and one that moves back and forth—to compress materials until they break. Jaw crushers are typically used for primary crushing, making them the first step in many crushing circuits before passing material to cone or impact crushers.

Compared to a cone crusher, which is better suited for secondary or tertiary crushing, the jaw crusher offers a robust and cost-effective solution for breaking down hard, abrasive materials like granite, basalt, and ore. Unlike an impact crusher, which crushes materials through high-speed collision, a jaw crusher delivers compression-based crushing, reducing wear and operating costs in certain applications.

2. Enhanced Output Through Optimized Chamber Design

One of the most significant innovations in modern jaw crushers is improved chamber geometry. Manufacturers are redesigning crushing chambers to ensure:

-

More uniform particle size output

-

Higher throughput rates

-

Reduced wear on jaw plates

The optimized angle between the fixed and moving jaw helps increase the crushing stroke, allowing for more material to be processed per cycle. This advancement makes the jaw crusher far more productive, especially when processing harder rock.

3. Advanced Materials for Better Durability

Jaw crusher components are now built using wear-resistant materials, such as:

-

High manganese steel

-

Alloy composite ceramics

-

Chromium-carbide overlays

These materials significantly extend the lifespan of jaw plates, toggle plates, and bearings, reducing maintenance downtime and long-term costs. In comparison, cone and impact crushers often face higher wear rates due to their rotational or impact-based crushing mechanisms.

Additionally, reinforced frames and bolted construction have replaced older welded frames in many models, making the structure more durable under intense workloads.

4. Hydraulic Adjustment and Automation

Modern jaw crushers feature hydraulic systems that allow for fast, safe adjustment of the CSS (closed side setting). This innovation reduces the need for manual tools or shims, increasing operational safety and enabling real-time production optimization.

Other automation features include:

-

Load sensing systems to prevent overload

-

Auto-lubrication for bearings and toggle systems

-

Integration with remote monitoring systems for diagnostics and performance tracking

This level of automation brings the jaw crusher in line with more technologically advanced crusher machines like cone crushers, which have traditionally been favored for precision and control.

5. Energy Efficiency and Reduced Environmental Impact

As environmental regulations tighten worldwide, jaw crusher designs are focusing on lower energy consumption and emissions. Energy-efficient motors, flywheel design optimizations, and balanced motion technology now help reduce electricity usage without sacrificing performance.

When compared to an impact crusher—which typically consumes more power due to its high-speed rotation—a jaw crusher provides a more eco-friendly solution for primary crushing, particularly in mobile setups.

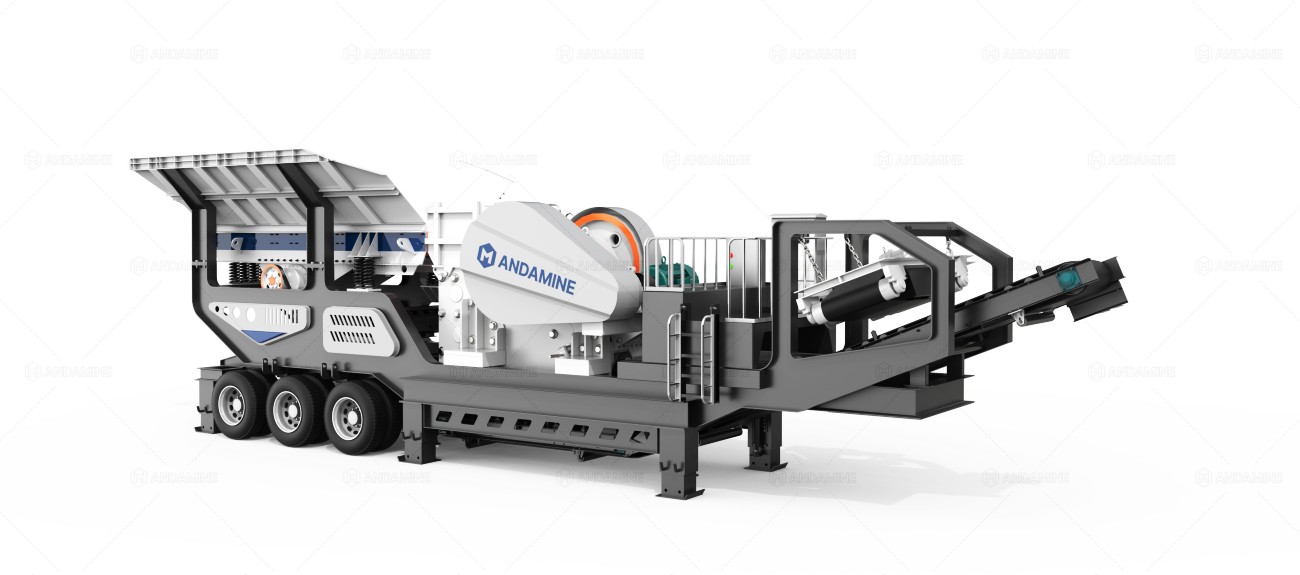

6. Modular and Mobile Jaw Crusher Platforms

Another trend shaping the future of jaw crushers is modularity and mobility. New machines are designed with modular skids or track-mounted systems, enabling quick relocation and flexible configurations on various job sites. The mobile crusher machine is especially valuable for:

-

Infrastructure and road projects

-

Temporary quarry operations

-

Urban construction sites where space is limited

This mobility also allows jaw crushers to work in tandem with cone crushers and impact crushers in a complete crushing line, enhancing operational flexibility.

7. Improved Safety Features

Safety has become a top design priority. Innovations in jaw crusher safety include:

-

Hydraulic toggle relief systems to release uncrushable material

-

Proximity sensors to detect human presence near moving parts

-

Better guarding and interlocked access doors

-

Non-slip maintenance platforms and easier access to wear parts

These features help reduce operator injuries and improve compliance with global occupational health and safety standards.

8. Comparative Role in a Crushing Circuit

Jaw crushers often work as part of a multi-stage crushing process. Here’s how they stack up with their counterparts:

| Crusher Type | Best Use | Strengths | Limitations |

|---|---|---|---|

| Jaw Crusher | Primary | Simple, robust, efficient with hard rock | Limited fine crushing capability |

| Cone Crusher | Secondary/Tertiary | Precise sizing, high throughput | Higher maintenance, complex |

| Impact Crusher | Secondary/Soft rock | Shape and gradation control | Higher wear on parts |

Innovations in jaw crusher design are now narrowing the gap—allowing it to compete even more strongly with cone and impact crushers, especially in terms of output efficiency and cost control.

Conclusion

The evolution of jaw crusher design over the past decade has been nothing short of revolutionary. From enhanced chamber geometry and wear-resistant materials to hydraulic automation, energy efficiency, and mobility, today’s jaw crushers offer unmatched performance in crushing operations.

For producers engaged in sand and aggregate production, mining, or recycling, investing in an advanced jaw crusher means lower operating costs, safer work environments, and greater long-term value. When used in combination with cone crushers or impact crushers, a well-designed jaw crusher becomes the backbone of an efficient and profitable crusher plant.