Barge winches are essential components of marine operations, playing a crucial role in the transportation and handling of heavy cargoes. Whether it’s loading and unloading cargo, positioning drilling rigs, or anchoring, barge winches are the workhorses of maritime industries. To ensure the efficiency and safety of these operations, it is imperative to install barge winches correctly. In this article, we will explore the methods and considerations for installing barge winches.

Understanding Barge Winches

Before diving into the installation methods, let’s briefly understand what barge winches are and their significance in maritime activities.

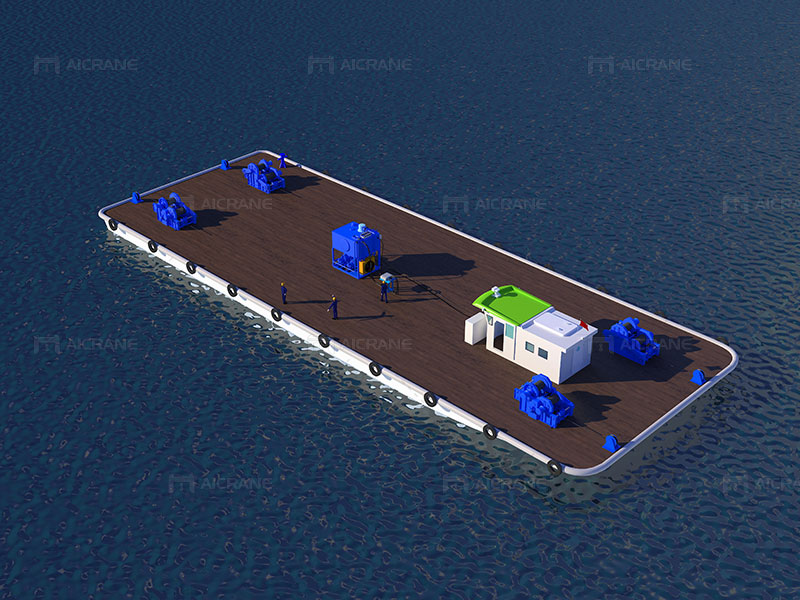

Barge winches are mechanical devices used to control the movement and positioning of barges, vessels, or other floating structures. They are designed to handle heavy loads and are often employed in offshore drilling, construction, and cargo transportation. Barge winches come in various types, including anchor winches, towing winches, and mooring winches, each serving a specific purpose in marine operations.

The installation of barge winches is a critical task that requires careful planning, precise engineering, and adherence to safety regulations to prevent accidents and operational inefficiencies.

Installation Methods

There are several installation methods for barge winches, each tailored to the specific requirements of the vessel and its intended use. Let’s explore some of the key installation methods in detail:

Deck-Mounted Installation:

Deck-mounted barge winches are commonly used in various maritime applications due to their versatility. This installation method involves securing the winch directly to the deck of the barge. Here are the steps involved in a typical deck-mounted installation:

a. Positioning: Determine the optimal location for the winch on the barge’s deck, taking into account the vessel’s structure, cargo handling needs, and weight distribution.

b. Mounting: Secure the winch to the deck using robust mounting brackets or foundations. Ensure that the mounting structure is adequately reinforced to handle the winch’s load capacity.

c. Power Source: Connect the winch to the vessel’s power source, which is typically a hydraulic or electric system, depending on the winch type.

d. Testing: Conduct thorough testing to ensure the winch functions correctly and can handle the anticipated loads. This includes load testing to verify its performance under different conditions.

Below-Deck Installation:

For some specialized applications, such as on smaller vessels or where deck space is limited, below-deck installation may be preferred. In this method, the winch is positioned below the barge’s deck, requiring more intricate engineering and design considerations:

a. Design: Collaborate with naval architects and engineers to design the ship winch system, considering factors like space constraints, weight distribution, and accessibility for maintenance.

b. Structural Reinforcement: Strengthen the barge’s hull and deck to support the below-deck winch system. Reinforce the deck with additional structural elements as needed.

c. Access and Maintenance: Ensure that there are appropriate access points and hatches for maintenance and repairs of the winch components located below deck.

d. Installation: Lower the winch and associated components into the designated below-deck location and secure them in place. Connect all necessary hydraulic or electrical systems.

Portable Winch Installation:

In some cases, particularly in temporary or emergency situations, portable winches can be used. Portable winches can be mounted and dismounted quickly, making them suitable for short-term projects or situations where flexibility is essential:

a. Mounting: Attach the portable winch to suitable mounting points on the barge’s deck using clamps or brackets. Ensure that the mounting is secure and stable.

b. Power Source: Connect the winch to a power source, such as a dedicated hydraulic pump or an electrical generator, depending on the winch type.

c. Operational Considerations: Portable winches should be carefully monitored during use to prevent overloading and ensure safety.

Safety Considerations

Regardless of the installation method chosen, safety should always be the top priority. Here are some essential safety considerations during barge winch installation:

Load Ratings: Ensure that the winch’s load rating is suitable for the intended application. Never exceed the winch’s capacity, as it can lead to equipment failure and accidents.

Regular Inspection: Implement a routine inspection and maintenance schedule to check for wear, damage, or corrosion in winch components. Address any issues promptly to prevent failures.

Operator Training: Provide comprehensive training to operators on the proper use of barge deck winches, including emergency procedures and safety protocols.

Environmental Considerations: Comply with environmental regulations and take measures to prevent oil or hydraulic fluid spills, which can have severe ecological consequences.

Emergency Shutdown: Install emergency shutdown systems to quickly stop winch operations in case of a malfunction or dangerous situation.

Conclusion

The correct installation of barge winches is essential for the efficiency and safety of maritime operations. Whether deck-mounted, below-deck, or portable, each installation method comes with its own set of considerations and challenges. Proper planning, engineering expertise, and adherence to safety protocols are crucial to ensure the successful installation and operation of barge winches. By following these guidelines and prioritizing safety, marine industries can continue to rely on these essential tools for their diverse applications.